Since 1950, the U.S. National Science Foundation has expanded the frontiers of manufacturing, funding breakthroughs such as nanomaterials, computer-aided design and 3D printing.

Manufacturing is essential to almost every sector of the global economy, from chemicals and electronics to food and medicine.

Technological advances are transforming manufacturing industries, promising more dynamic and efficient products that improve people's lives, strengthen the national economy, create higher-paying jobs, and enhance U.S. competitiveness on a global stage.

On this page

On this page

Brought to you by NSF

NSF's decades of sustained investments have ensured the continual advance of manufacturing research. Pioneering work supported by NSF includes:

Computer-aided design

Research by NSF-funded scientists into solid modeling enabled widespread use of computer-aided design, which has revolutionized manufacturing processes across the globe.

Digital twin modeling

Foundational investments by NSF led to the development of digital twin modeling, a widely used approach that allows engineers to simulate how a product, process or system will perform before they make changes to it.

3D printing

Early NSF-funded research in additive manufacturing played a pivotal role in the development of 3D-printing techniques.

What we support

Innovation in advanced manufacturing

We enable discoveries that lead to products and processes with higher performance; new capabilities; better safety, security and privacy guarantees; and the use of fewer and more-sustainable resources.

Enabling tomorrow's manufacturing industries

We support research in emerging areas to enable industries that do not exist today, with a focus on cyber-, eco- and bio-manufacturing research advances and human-centered automation.

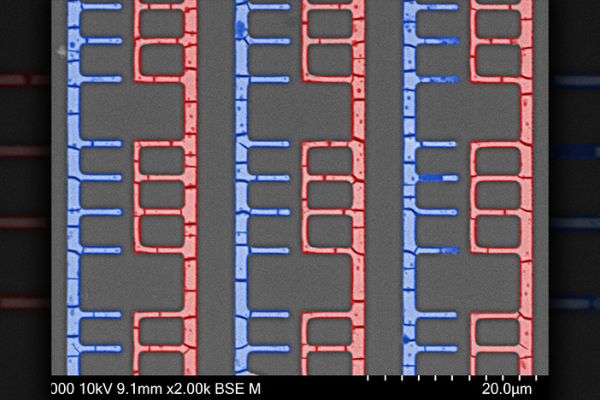

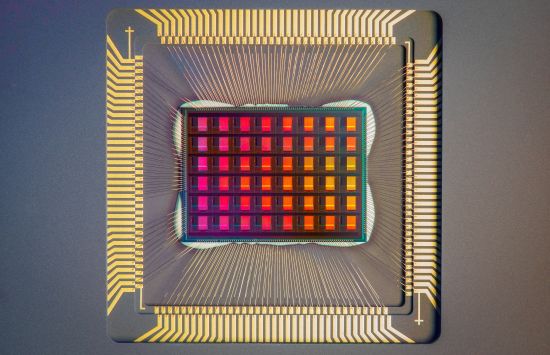

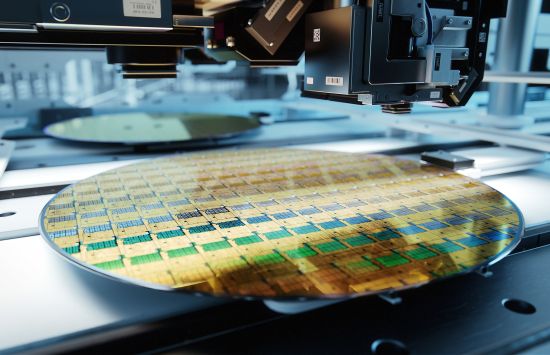

Next-generation semiconductors and microelectronics

We support research on the design, fabrication and manufacture of new semiconductor technologies using advanced and sustainable materials, techniques and processes.

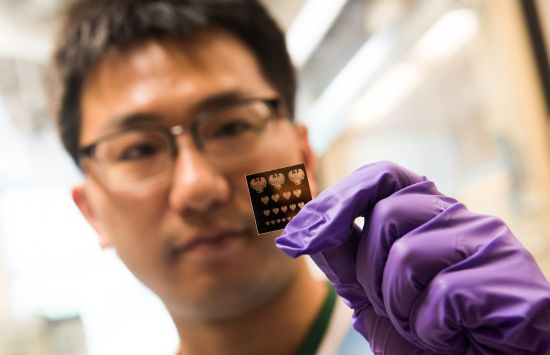

Biomanufacturing to grow the bioeconomy

We support research that harnesses biology to manufacture therapeutic cells and molecules, chemicals, fuels and other products, as well as the development of bio-based technologies for computing, communication and other uses.

Research infrastructure for manufacturing

We support the development of research tools and testbeds necessary to characterize, fabricate and test materials, processes and technologies while enabling access to semiconductor and biomanufacturing foundries.

Education and workforce development

We support efforts to attract, educate, train and reskill/upskill diverse workers from across the nation, from K-12 to college and industry, for the manufacturing workforce of the future.

Partnerships to accelerate progress

We partner with other federal agencies, industry and nonprofits to share data, tools, expertise and other resources; strengthen workforce development; and translate research into products and services that benefit society.

Foundational Research in Robotics

Scientists and engineers are developing robots that can handle critical tasks — from manufacturing to caring for the elderly — with greater dexterity and safety than previous generations of intelligent machines.

NSF's Foundational Research in Robotics program supports research on robotic systems that exhibit significant levels of both computational capability and physical complexity.

Featured funding

Advanced Manufacturing

Supports fundamental manufacturing research that addresses issues related to national prosperity and security and has the potential to contribute to the revitalization of American manufacturing.

America's Seed Fund (SBIR/STTR)

Supports startups and small businesses to translate research into products and services, including advanced manufacturing and robotics, for the public good.

Design for Environmental Sustainability in Computing

Supports foundational research addressing the substantial environmental impacts of computing. Projects should surpass studies of energy efficiency alone, pursuing dramatic improvements to overall sustainability.

Experiential Learning for Emerging and Novel Technologies

Supports inclusive experiential learning opportunities that provide cohorts of diverse learners with the skills needed to succeed in advanced manufacturing and other emerging technology fields.

Future Manufacturing

Supports fundamental research and education of a future workforce to overcome scientific, technological, educational, economic and social barriers in order to catalyze new manufacturing capabilities that do not exist today.

Manufacturing Systems Integration

Supports research into the opportunities and challenges that digital technologies present for the next industrial revolution — such as connectivity, automation and secure collaboration — and their roles in global manufacturing.