3D-printed shape memory alloy is engineered with superelasticity

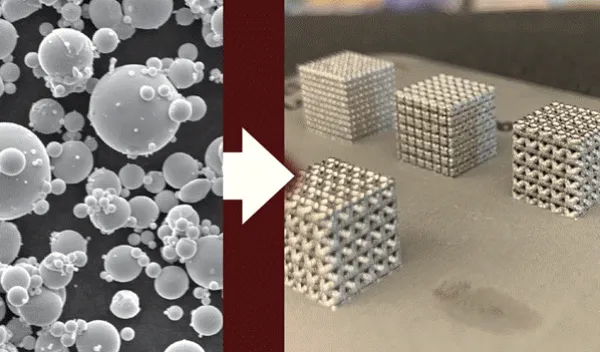

Engineers at Texas A&M University conducting a study supported by the U.S. National Science Foundation have created a superelastic shape memory alloy using 3D printing. Their method avoids defects like warping and delamination that commonly occur when 3D printing with laser powder bed fusion.

Nickel-titanium shape memory alloys are used in a variety of aerospace and biomedical applications, such as airplane wings and surgical devices, due to the ability to revert to their original state after heat or stress is applied. However, because of the expensive and resource-intensive manufacturing process, the use of nickel-titanium shape memory alloys has been limited.

"Shape memory alloys are smart materials that can remember their high-temperature shapes," said Lei Xue, first author of the paper. "Although they can be used in many ways, fabricating shape memory alloys into complex shapes requires fine-tuning to ensure the material has the desired properties."

The technique uses a laser to fuse metal or alloy powders layer by layer to fabricate objects with complex geometries prohibited by the means of traditional manufacturing.

"Using a 3D printer, we spread the alloy powder over a substrate and then use the laser to melt the powder, forming one full layer," said Xue. "We repeat this layering, scanning the same or different patterns, until the desired structure is formed."

Most nickel-titanium materials are damaged during a typical laser powder bed fusion process. The researchers used a framework to select optimal parameters to prevent defects and fabricate nickel-titanium parts that consistently have a room temperature tensile superelasticity of 6% without post-printing treatments — almost double the amount previously documented. Producing shape memory alloys with superelasticity through 3D printing results in a more efficient and affordable manufacturing technology.

Xue added, "This study can serve as a guide on how to print nickel-titanium shape memory alloys with desired mechanical and functional characteristics. If we can tailor the crystallographic texture and microstructure, there are far more applications these shape memory alloys can be used in."

The breakthrough has the potential to increase the scalability of 3D-printed nickel-titanium shape memory alloys.