College using 3D printers to make face shields for regional hospital

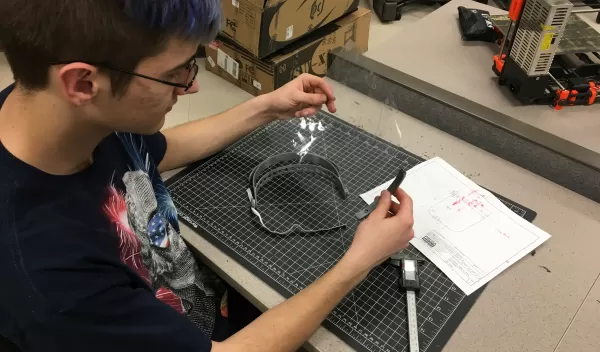

Somerset Community College, in Somerset, Kentucky, is putting its 3D printers to work to create face shields that will help Lake Cumberland Regional Hospital amid a supply shortage in the fight against COVID-19.

The work is supported through an award from the National Science Foundation's Advanced Technological Education program to educate technicians for advanced-technology fields such as 3D printing, also known as additive manufacturing.

Professor of Additive Manufacturing Eric Wooldridge responded to a request from partnering networks and the state to see if local colleges could help print a newly released prototype for face shields. Printers in the college's Additive Manufacturing Center of Excellence are running 24/7 and producing approximately 100 face shields a day. The college plans to produce enough to supply Lake Cumberland Regional Hospital and other healthcare facilities.

"The 3D printing community has stepped up immediately in a very big way. Some of the things we are currently producing did not even exist just days ago," said Wooldridge.

Although the lab is producing a large number of shields, Wooldridge noted, "We have learned from this experience … we need more people trained on this technology."

"The Advanced Technological Education program is enabling much-needed preparation for people to work in fields that drive the nation's economy and, as we see in Somerset Community College's production of face shields, to meet crucial societal needs," said Celeste Carter, a program officer in NSF's Division of Undergraduate Education.