Improving helmets to reduce impact of concussions

It wasn’t exactly like the lightbulb moment you might have seen in the movies or on TV, but Nick Cecchi had a revelation after suffering a hit to the head.

“My second year of college, I sustained a pretty serious concussion at a practice during water polo,” Cecchi said. “There was a professor at UC Irvine, Dr. James Hicks, who was leading the world's first study on head impacts and concussion in water polo using wearable impact sensors. So me being a water polo player pursuing an engineering degree and having the recent brain injury, I reached out to him and quickly got involved in the research.”

Today, Cecchi is a graduate student at Stanford University working under Dr. David Camarillo, where he focuses on researching concussions and developing solutions to reduce the number suffered by athletes and lessen the long-term impacts.

“Concussion symptoms are usually things like headaches, nausea, blurred vision, sensitivity to light, maybe slurred speech, changes in mood and behavior. There's a lot of different symptoms that can come with it,” he said. “These symptoms can last on the scale of a few days for very mild concussions, but they can even last up to several months and manifest as post-concussive syndrome. Concussions aren't the only problem though. There's actually sub-concussive impacts, which won't present with any immediate symptoms, but the cumulative burden of these repeated sub-concussive head impacts, like football players sustain over the lifetime of a career, have been linked to later life neurodegenerative diseases like chronic traumatic encephalopathy, or CTE.”

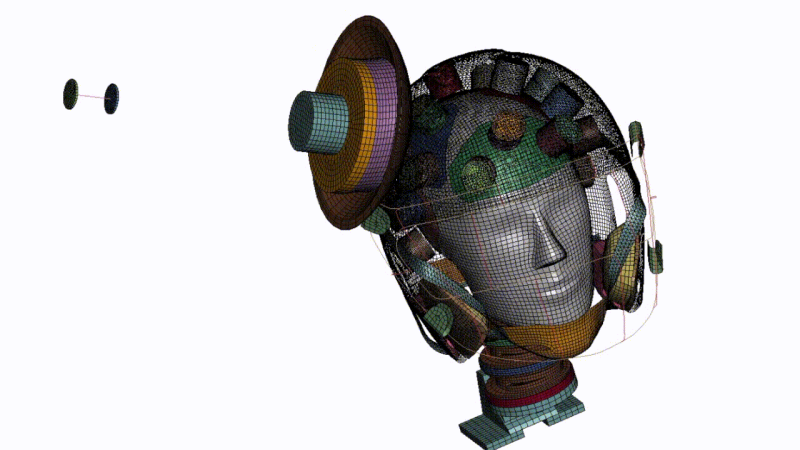

One of Cecchi’s efforts is a football helmet that is lined with 21 liquid shock absorbers. Tests on a model of the helmet showed that it can reduce the severity of concussive and subconcussive impacts by 33 percent compared to existing popular models – based on the Head Accelerate Response Metric, which is used to evaluate how well helmets absorb impacts.

Cecchi, a recipient of a U.S. National Science Foundation Graduate Research Fellowship, spoke with NSF about his work and its potential implications.

How do liquid shock absorbers improve the impact performance of helmets?

Cecchi: We need to choose a shock absorber that will give protection for all kinds of impacts, because especially in football, we have those slow, small, repeated head impacts, and then we get some big ones that are going to cause concussions or more serious events.

Traditionally, foams have been used in helmets, and the foams that are used exert a force based on how much they're compressed. This isn't ideal, because it leads to foams being tuned for a very specific range of impacts. So if the foam is tuned for a really slow impact, the foam is going to compress down and reach its maximum too early and it'll bottom out. That means the foam won't be able to do any more work, and it will lead to a high spike in the impact force when a fast impact comes. Now if a foam is tuned for a really severe impact like a concussive impact, it'll make the foam too stiff to help for the repeated sub-concussive impacts that are slower, that'll build up over a lifetime. So the reason we chose liquid is because we needed a technology that's adaptive to different velocities.

How does a liquid shock absorber work?

Cecchi: The liquid shock absorbers that we've made was inspired by the hydraulic shock absorbers that are used in, for example, your vehicle's suspension system. Hydraulic shock absorbers can adapt to provide a soft response at different velocities. However, in a helmet, we obviously can't have big, rigid metal components like you have in your vehicle's suspension system. So our design uses the same principles of hydraulic shock absorption but is made out of all soft components.

We've got on the outside a high-strength fabric that surrounds a liquid that's contained in a central chamber. When the shock is compressed, fluid ejects out laterally to a part in the helmet that presumably would not be under impact. And then after the impact is over, that fluid comes back into the central chamber. Now one more thing is that there actually are some foams that can adapt their response to different velocities, like viscoelastic foams. However, their performance is really sensitive to changes in temperature. So if you get too hot, those foams get really soft. If you get too cold, the foams really stiffen up and they don't work like they're supposed to. What we've observed in our some of our experimental studies is that as long as we're not picking a fluid that freezes, like water, or evaporates with temperature changes, we achieve very consistent results with the liquid shock asborber when we change the temperature of the impact environment. So we're still getting that adaptive response in a wide range of settings.

How do you test the helmets?

Cecchi: We have two main test setups. One is for testing helmet materials at the component level. We want to see how does the shell, how does the shock absorber, how does the comfort padding all respond to a uniaxial impact? And then we've also got full helmet tests where we've got helmets that are fit onto a crash test dummy and a big impact ram slams into them at velocities representative of concussions on the field. For the helmet shock absorber test – those component level tests – we're really just looking at how does the material itself behave when different sorts of loading are input to that shock absorber system. We drop a mass onto the shock absorber and measure the force with a force plate. For the helmet tests, we're looking at what happens to the head and brain and neck when a full helmet system is placed on that dummy. The dummy head has sensors mounted inside of it that tell us how rapidly the head moves after an impact. We also use high-speed video cameras to get a detailed look at every impact test.

Have you built a prototype for testing on the field?

Cecchi: We’ve built several prototypes of helmets for various sports and tested them extensively in the lab. The results have been very promising. However, when you design a product meant to go on the field, there's more that goes into it than just the safety performance. The company Savior Brain will be commercializing the technology under the name “SoftShox,” and we still have to work on things like the comfort and the aesthetics before a liquid helmet is available for field use. There's a big translation ahead where we need to focus on making our liquid shock absorbers look and feel like a really nice product, and not just a fascinating science project.

Could we zero out concussive risk with the right kind of helmet?

Cecchi: It's a lofty goal, for sure, but I do think that it's possible. If we look back several decades at skull fractures and more serious life-threatening head injuries, they used to be relatively common in the sport of football. But once the right injury metrics were used to evaluate those risks and standardized testing organizations – like NOCSAE – implemented regulations for helmet technologies to advance and meet certain safety criteria, it nearly eliminated that type of injury. We don't really see those hardly at all in football anymore. So I believe this is something that we could see with concussions one day.

Technology is definitely a major part of the solution, but we're going to need a multi-pronged approach to solving concussions. And right now, I think that would first start with better helmet technology, but also rule changes that promote safer gameplay. We're going to need constant head impact monitoring with devices like instrumented mouthguards to remove players who are taking too much burden and also improved education for athletes, coaches, and training staff to really let everybody know how serious concussion is.

Hear more from Cecchi, including the impact of NSF support on his career, the difficulty in diagnosing concussions and research on using mouthguards to measure the impacts of hits during play.