Fiber-infused ink enables 3D-printed heart muscle to beat

Over the last decade, advances in 3D printing have unlocked new possibilities for bioengineers to build heart tissues and structures. Their goals include creating better in vitro platforms for discovering new therapeutics for heart disease — the leading cause of death in the United States, responsible for about one in every five deaths nationally — and using 3D-printed cardiac tissues to evaluate which treatments might work best in individual patients.

A more distant aim is to fabricate implantable tissues that can heal or replace faulty or diseased structures inside a patient's heart.

In a U.S. National Science Foundation-supported paper published in Nature Materials, researchers from the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) report the development of a new hydrogel ink infused with gelatin fibers that enables 3D printing of a functional heart ventricle. They discovered the fiber-infused gel (FIG) ink allows heart muscle cells printed in the shape of a ventricle to align and beat in coordination like a human heart chamber.

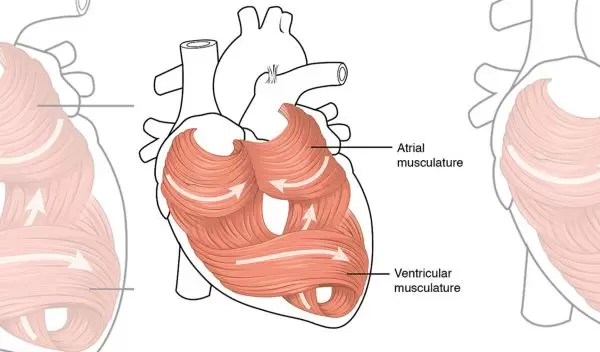

"People have been trying to replicate organ structures and functions to test drug safety and efficacy as a way of predicting what might happen in the clinical setting," says Suji Choi, research associate at SEAS and first author of the paper. But until now, 3D printing techniques alone have not been able to achieve physiologically relevant alignment of cardiomyocytes, the cells responsible for transmitting electrical signals in a coordinated fashion to contract heart muscle.

"We started this project to address some of the inadequacies in 3D printing of biological tissues," says Kevin "Kit" Parker, head of the Disease Biophysics Group at SEAS and senior author of the paper.

The innovation lies in the addition of fibers within a printable ink. "FIG ink is capable of flowing through the printing nozzle but, once the structure is printed, it maintains its 3D shape," says Choi. "Because of those properties, I found it's possible to print a ventricle-like structure and other complex 3D shapes without using extra support materials or scaffolds."

As Choi printed 2D and 3D structures using FIG ink, the cardiomyocytes lined up in tandem with the direction of the fibers inside the ink. By controlling the printing direction, Choi could therefore control how the heart muscle cells would align.

When she applied electrical stimulation to 3D-printed structures made with FIG ink, she found it triggered a coordinated wave of contractions in alignment with the direction of those fibers. In a ventricle-shaped structure, "it was very exciting to see the chamber actually pumping in a similar way to how real heart ventricles pump," Choi says.