'Green electrospinning' process has potential to transform biofabrication

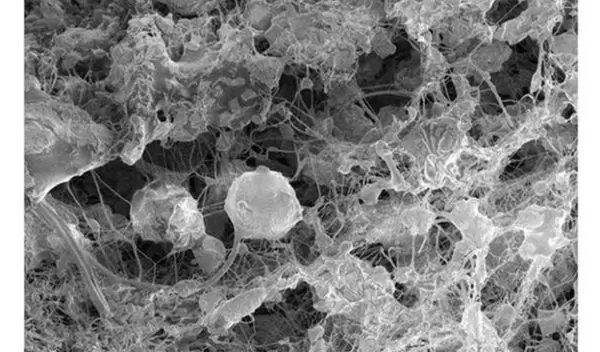

Electrospinning is a fabrication technique used to create fibrous meshes similar to natural tissue that can be produced at a nano- to microscales. Historically, electrospinning involved the use of hazardous solvents that damage the environment and make broad use of the process unfeasible.

A U.S. National Science Foundation-funded report by researchers at Columbia Engineering details a "green electrospinning" method that mitigates the environmental and hazardous material disposal risks of traditional electrospinning while satisfying health and safety protocols. Green electrospinning is an eco-conscious and scalable biofabrication process that replaces traditional solvents with biologically benign solutions. By using this method, adverse impacts of the manufacturing process may be reduced three to six times.

The study also demonstrates that the advantages of green manufacturing aren't limited to reducing environmental impacts. The "green fibers" examined displayed mechanical properties and growth similar to traditional fibers, making the synthetic materials viable for use in drug delivery and tissue engineering. Green electrospun materials are already being developed for use in dental and orthopedic applications.

Scalable and sustainable manufacturing of biomaterials has the potential to transform the production of regenerative medicine applications, scientists have found. This innovative approach dramatically reduces the negative health and environmental aspects of the process and will continue to revolutionize the fabrication of natural and synthetic polymers, researchers say.