New class of light-powered polymer catalysts could improve pharmaceutical manufacturing

Chemical reactions powered by light require photoredox catalysts that convert light into a chemical reaction. Chemists based at MIT, supported by a grant from the U.S. National Science Foundation, have developed a new class of photoredox catalysts that could add efficiency to the manufacturing process. The new photoredox catalyst polymer is insoluble and can be used to coat surfaces to transform reactants.

"Being able to recycle the catalyst is one of the biggest challenges to overcome in terms of being able to use photoredox catalysis in manufacturing,” said Richard Liu, joint lead author of the study. “We hope that by being able to do flow chemistry with an immobilized catalyst, we can provide a new way to do photoredox catalysis on larger scales."

The photoredox catalyst polymer can be used in a variety of reactions and could be adapted for use with other materials. The photoredox polymer is a hybrid of heterogenous and homogeneous catalysts, making them easy to adapt and reusable. The researchers demonstrated that multiple different homogenous catalysts could be incorporated into the new hybrid polymer material.

"These hybrid catalysts have the recyclability and durability of heterogeneous catalysts, but also the precise tunability of homogeneous catalysts," Liu said. "You can incorporate the dye without losing its chemical activity, so you can more or less pick from the tens of thousands of photoredox reactions that are already known and get an insoluble equivalent of the catalyst you need.”

The polymer catalyst the team developed eliminates the need to continuously replenish the catalyst during photoredox reactions that require a continuous flow process.

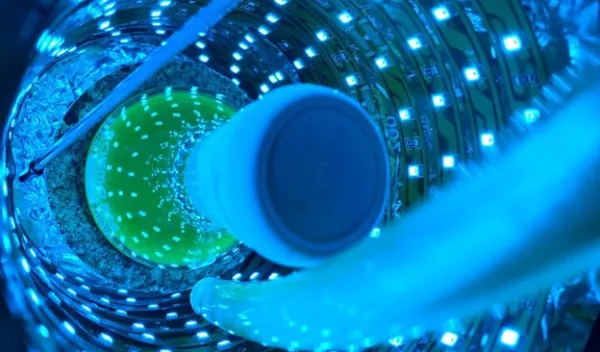

"The idea is to have the catalyst coating a tube, so you can flow your reaction through the tube while the catalyst stays put,” Liu said. “In that way, you never get the catalyst ending up in the product, and you can also get a lot higher efficiency."

Birgit Schwenzer, program director in NSF's Division of Materials Research, added, "The idea to use microporous organic solid-state materials, for example, as coatings and catalysts simultaneously is new and exciting. That the material is chemically stable but also can be recycled is an added benefit since it could be a step toward a circular economy."