New technology uses natural wood fibers to reinforce plastic materials

Joshua Otaigbe's research blends chemical engineering with materials structure and properties, most recently in trying to develop new and stronger composites that are sustainable and environmentally friendly.

The longtime National Science Foundation (NSF)-funded scientist, a professor in the University of Southern Mississippi's school of polymers and high performance materials, is collaborating with researchers at Oregon State University on a new technology that uses natural wood fibers to reinforce plastic materials.

If successful, "it could revolutionize the composite industry," especially manufacturing sectors that rely on these materials, such as building, construction, automobiles, and aircraft, he says.

Moreover, "wood fiber is renewable and based on agricultural products, and the composite materials we come up with would biodegrade after their service life without harming the environment," he adds.

Greater use of wood fibers in producing composites also could be a boost to the paper industry by providing an important new use for wood pulp, since "paper is a raw material for our products," he says. "We can extract wood fibers out of paper."

NSF is funding the work through its structural materials and mechanics program of the division of civil, mechanical, and manufacturing innovation. Otaigbe is collaborating with John Nairn, the Richardson Chair in wood science and engineering at Oregon State University; the two researchers are sharing the grant.

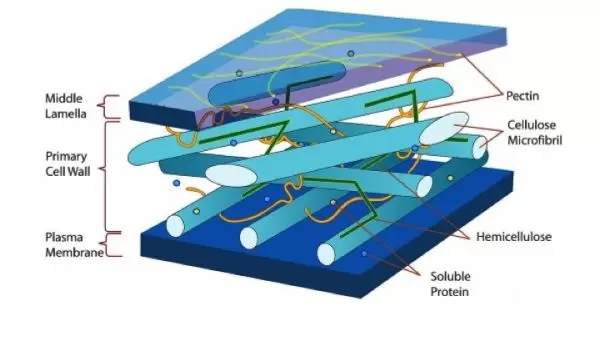

Currently, the composite industry combines wood particles--not fibers--with its polymers, "which saves money, but is a less than optimum way of doing it," Otaigbe says. "What we are doing is extracting fibers, which are different from particles. The fiber is a lot stiffer and stronger than the wood particles, and provides the reinforcing capability for the plastic."

Using wood fibers instead of particles in the direct conversion of the polymer building blocks called monomers also allows manufacturers to eliminate the melting stage, which is when the materials are shaped, then later solidified into various products. With fibers in the polymer matrix, "we can shape it without having to melt it," Otaigbe says.

The process under development involves taking the wood fibers, usually within paper, and placing them in a mold, then injecting a "reaction" mixture used to make the polymers.

Scientists then raise the temperature to 150 degrees Celsius--relatively low when compared to traditional melting methods--and the mixture forms a composite "in a matter of minutes," he says. The lower temperatures are important, since wood fibers tend to degrade at temperatures above 190 degrees Celsius.

Otaigbe has long worked on NSF-funded projects that combine polymer materials structure with chemical engineering, and also has been actively involved in university and industry research partnerships to try to solve complicated and multi-disciplinary problems.

"What I'm doing, with industry, is using my background and experience to solve relevant technical problems," he says.

For example, NSF and the Arnold Engineering Co., a U.S. manufacturer of magnets, jointly funded his research into advanced polymer bonded magnets with enhanced magnetic properties for high temperature and aggressive environments.

"Permanent bonded magnets are a $500-million market and are used in consumer products from cars to computers," he says. "But they are made from rare earth metal alloys, which are heavy and difficult to process into shapes. A need exists to develop bonded magnets with higher energy products that can withstand operating temperatures of at least 180 degrees Celsius and higher. One key issue is the identification of suitable magnetic powders and polymer matrices which can perform satisfactorily at the desired higher temperatures."

Otaigbe is the rare researcher who has simultaneously received grants from numerous NSF programs--metals, ceramics, polymers, and also from its engineering section.

He has, for example, conducted research into the feasibility of incorporating functional nanoscale fillers into waterborne polyurethanes to yield new hybrid films with improved performance properties, such as enhanced bioactivity and non-thrombogenicity (non-clot producing in the blood), thermal stability, flame resistance, environmental durability in atomic oxygen, and improved mechanical properties.

"The targeted hybrids, which are different from conventional polymers, polymer nanocomposites and microcomposites, would be useful because many of the intrinsic properties of the [new hybrids] are complementary, and hold great promise for future high-end uses, such as in biomedical devices, especially at cardiovascular interfaces, where other polymers are not useable," he says.

He also has studied ways to generate nano-structured hybrid glass/organic polymer materials via molecular level mixing of the components in the liquid state, creating novel hybrids impossible to produce using conventional methods.

"The self-organized structures, ranging from nanometer to micrometer length scales, are thermodynamically stable because the inorganic phases are mixed at the molecular level, that is, from a single phase, during processing," he says.

"The plastics industry expects a lot from advanced materials, but the relatively few that are commercially available cannot satisfy all applications and expectations," he adds. "In this context, nano-structured hybrid organic-inorganic glass thermoplastic materials potentially demonstrate all the benefits of traditional filled plastic composites, and avoid their disadvantages."

These products could translate into improved energy efficiency for such applications as high-powered laser fusion systems, biomaterials, storage materials for nuclear wastes, and as a component in load-bearing organic-inorganic hybrid composites, he says.

Also, he has worked to create new soy protein plastics derived from renewable agricultural products, designed to biodegrade safely. "One major problem with soy protein plastics is that they dissolve too quickly in water, limiting their potential uses," he says. "The new formulation makes the material more moisture resistant, providing greater control over the biodegradation process."

The research could lead to several new uses for soy protein plastics, for example, in packaging, medical sutures and sporting goods, he says.

Recently, he received an appointment naming him the Distinguished Chair in Polymer Materials Science and Engineering at the University of Lyon, the largest science and engineering university in France, as a recipient of the Fulbright-Tocqueville Distinguished Chair in France, and taught there during the spring semester.